Scalar indices, which are derived from time series, extract specific information, by discarding other information from the data set: by contrast, high-resolution time series contain a large number of individual values, and thus more information about the course of a cycle. Scalar values, such as the maximum injection pressure or the switchover injection pressure, represent only one value at a specific point in time during the molding process. demonstrated another approach, whereby features were generated from cavity pressure curves, by forming integrals for quality prediction in a multi-cavity injection molding process. extended this approach, by integrating an autoencoder network for automated feature extraction. used indices (integrals and maxima) extracted from cavity pressure and injection pressure curves, and achieved promising prediction accuracy for geometric dimensions, using a multilayer perceptron mesh model. Recent work has shown that scalar features derived from time series are relevant, in the context of part quality prediction, and can lead to an improvement in prediction accuracy. A time series usually includes injection pressure over time, injection flow over time, and cavity pressure over time. Time series can be continuously collected from a machine’s internal sensors throughout each injection molding cycle.

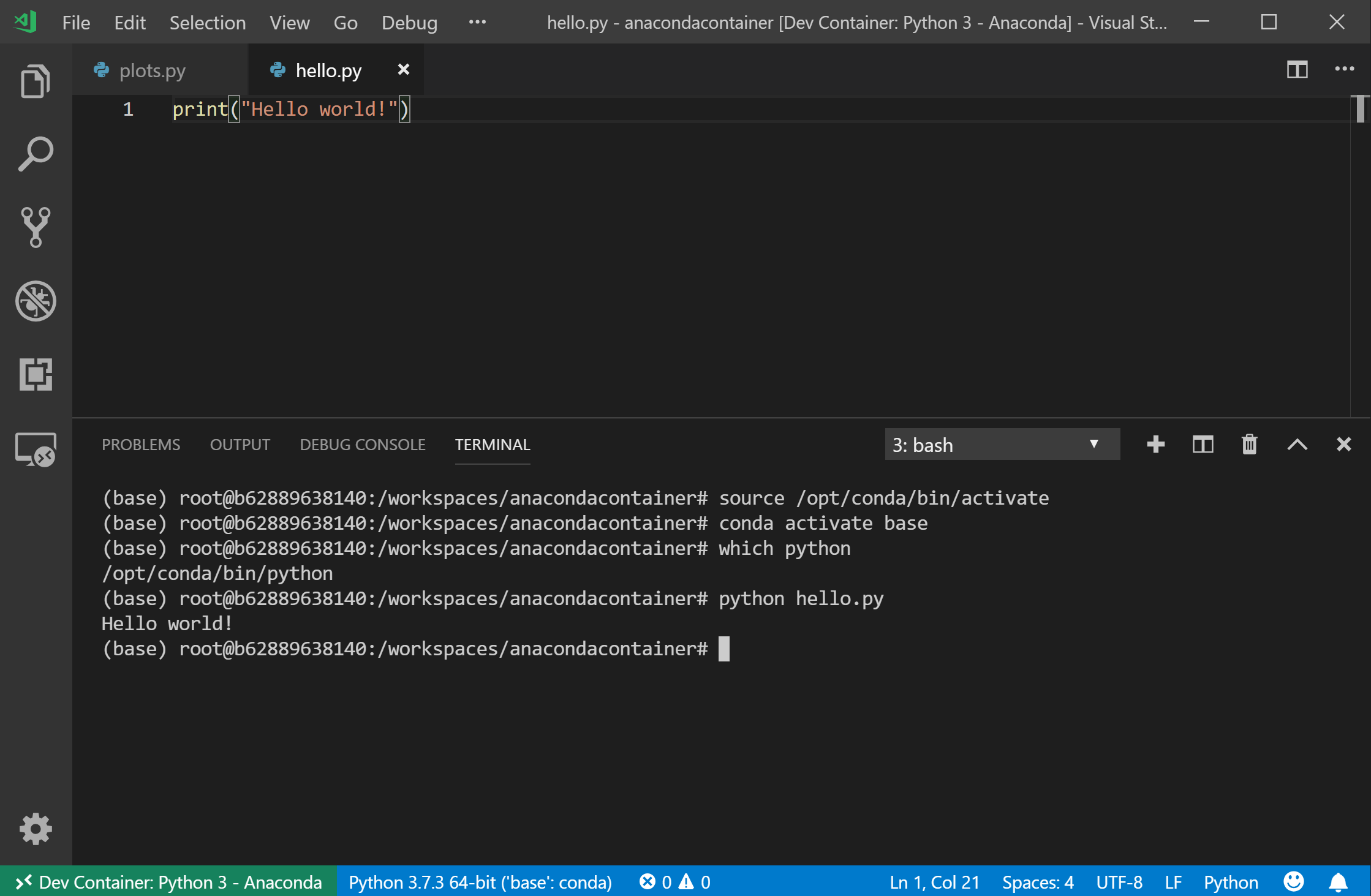

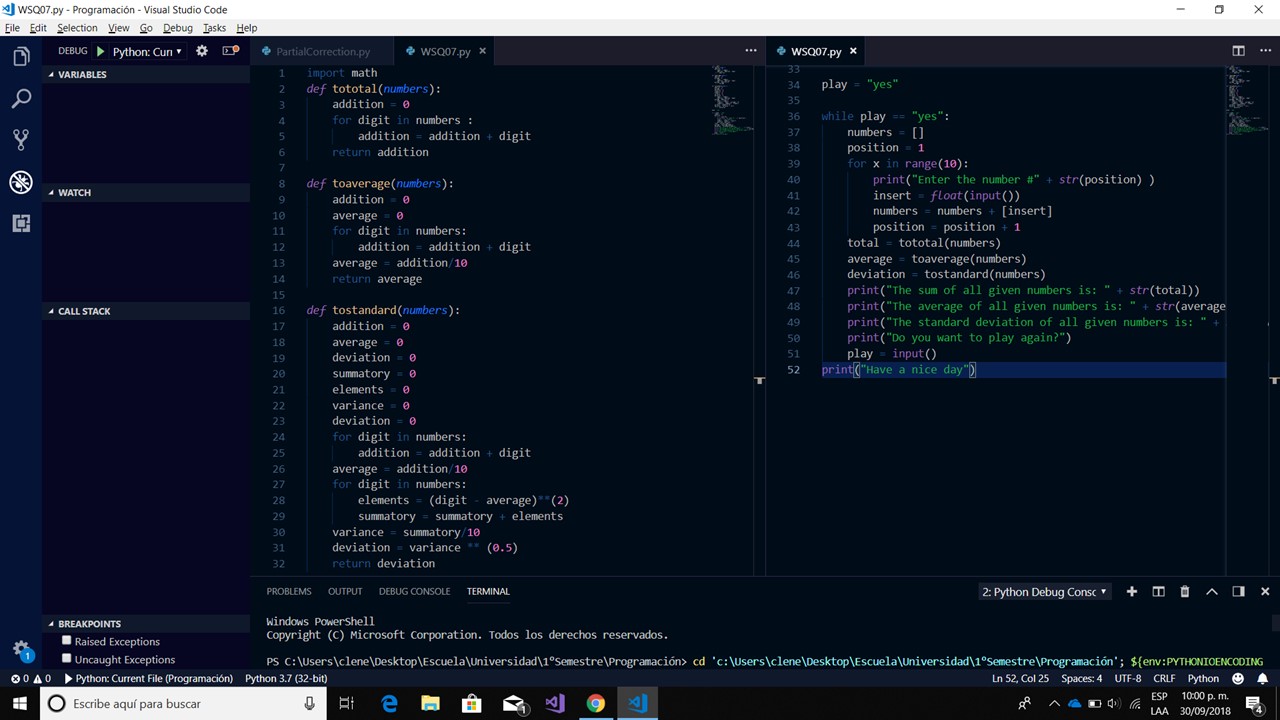

#ATOM PYTHON RUNNER USER INPUT FULL#

In this paper, we investigated the use of full time series of sensor measurements in place of, or in addition to, such scalar features.

Recent work has shown that part quality prediction is possible using machine learning (ML) algorithms: in this context, the features that serve as input for the algorithms are measurements represented as scalar values, i.e., single numerical aggregates, such as maximum injection pressure, residual mass cushion, and metering time. The main purpose of the sensors is internal process control: if the sensory process data can be made available, it can also serve additional purposes, e.g., the predicting of molding quality without explicitly measuring it on the product. In contrast to such part quality data measurements, process data from a machine’s internal sensors are already provided within standard injection molding machine controls. Predicted quality properties can be used similarly to measured ones, e.g., for the evaluation of process capability however, permanent automatic online measurement of gravimetric and geometrical quality properties on every injection molding machine is not an option for most industrial applications, due to the high costs of such measurements (manual work or dedicated additional hardware). Consistency in the part quality properties of the molded parts is crucial for every processor. One approach to detecting process instabilities in the injection molding process is to predict the quality properties of the molded parts.

0 kommentar(er)

0 kommentar(er)